The problem

Our renovation system - your advantages

Our system products

Swap bodies and trailers are efficient solutions for the transport of goods in combined transport, reducing costs and CO2 emissions.

However, there is also a major disadvantage to using these systems!

The use of swap bodies at the loading gates and parking areas leads to high mechanical stress and wear on the parking space surfaces .

This results in deformations and depressions that pose a risk of accidents, can damage the swap bodies and create a visual defect.

The damage is further aggravated by vibrations during loading and unloading.

This particularly affects concrete, paving and tar surfaces, whereby even high-quality concrete surfaces cannot withstand the loads.

Although the damage caused by the shod parking supports of trailers is less, it still occurs frequently, especially on tarred and paved surfaces.

Your operations at the gates will be interrupted for a maximum of 2 hours!

We manufacture our highly resistant ProBo plastic and concrete panels in-house . Round versions with diameters of 400 and 500 mm and oval versions with diameters of 400/600 mm . The panels are very abrasion-resistant and only minimal wear occurs over the years.

With our own specialist staff and professional equipment, we install our panels in all types of road surfaces .

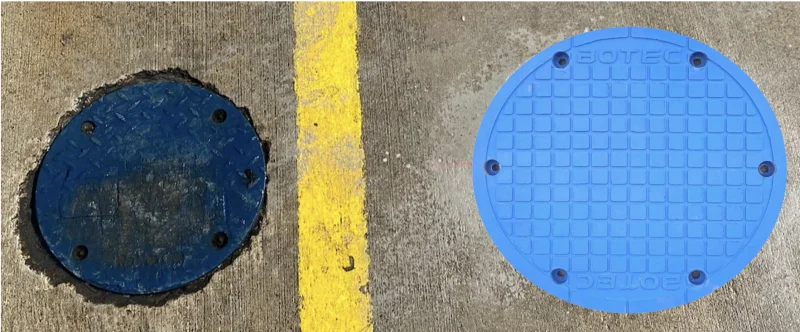

In practice it has been shown that for some applications the diameter of 400mm is too small.

The result was breakouts caused by the swap bodies not being placed at the correct location.

That is why we laid down and installed our 500mm panels from mid-2021.

For the renovation and subsequent long-term protection of the parking spaces, we install ready-made building elements in various designs and price ranges.

All elements have undergone rigorous quality tests, are tried and tested, high quality and durable, with a 10-year guarantee.

Our own production makes us flexible and independent. This means we can guarantee you on-time installation.

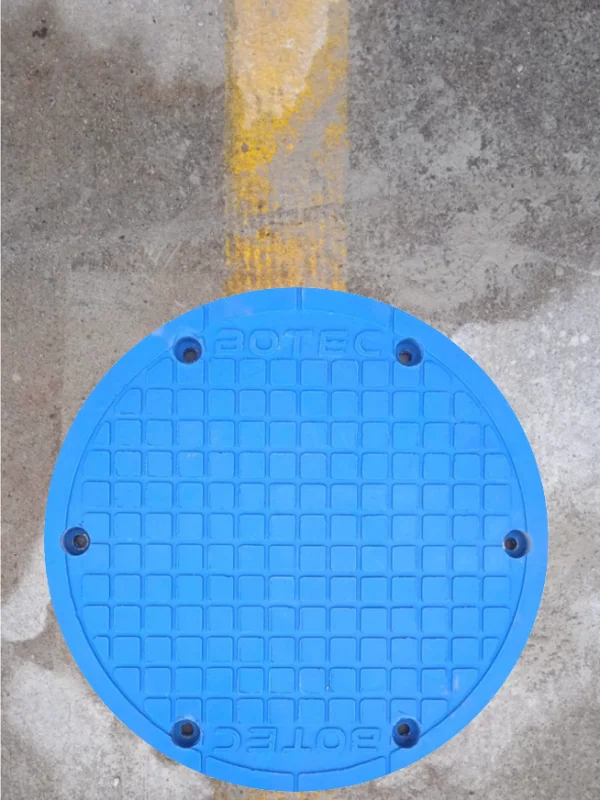

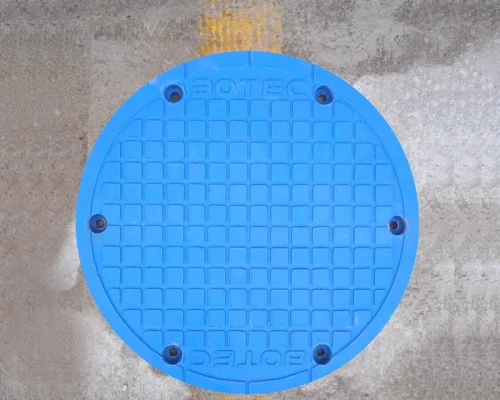

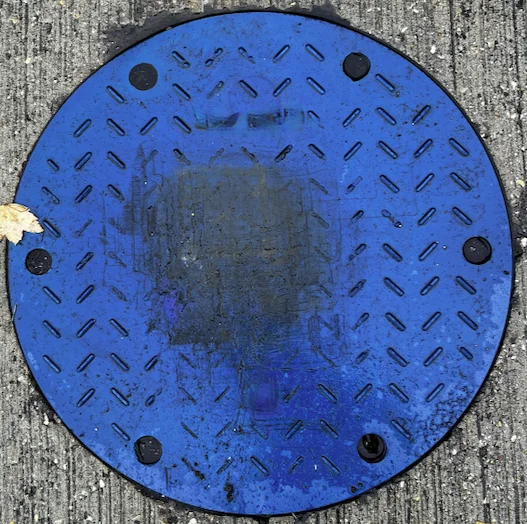

The plate is installed at ground level with the parking space and is the most commonly installed variant.

Highly durable plastic. Very abrasion-resistant, dimensionally stable and weatherproof.

Standard is blue, red and yellow. Available in any color for an additional charge, e.g. in your corporate color.

The plate is installed at ground level with the parking space and is the most commonly installed variant.

Highly durable plastic. Very abrasion-resistant, dimensionally stable and weatherproof.

Standard is blue, red and yellow. Available in any color for an additional charge, e.g. in your corporate color.

The plastic/steel combination is installed with the flange thickness increased to the parking space area.

This special construction optimally protects the edge areas of the repair points against damage if the swap bodies or trailers are not set down precisely.

It is a highly recommended variant that combines appearance and function in the best possible way.

Highly resistant plastic with steel frame and steel flange. The plastic is very abrasion-resistant, dimensionally stable and weatherproof. The steel components are high-quality hot-dip galvanized.

Standard is blue, red and yellow. Available in any color for an additional charge, e.g. in your corporate color.

The plastic/steel combination is installed with the flange thickness increased to the parking space area.

This special construction optimally protects the edge areas of the repair points against damage if the swap bodies or trailers are not set down precisely.

It is a highly recommended variant that combines appearance and function in the best possible way.

Highly resistant plastic with steel frame and steel flange. The plastic is very abrasion-resistant, dimensionally stable and weatherproof. The steel components are high-quality hot-dip galvanized.

Standard is blue, red and yellow. Available in any color for an additional charge, e.g. in your corporate color.

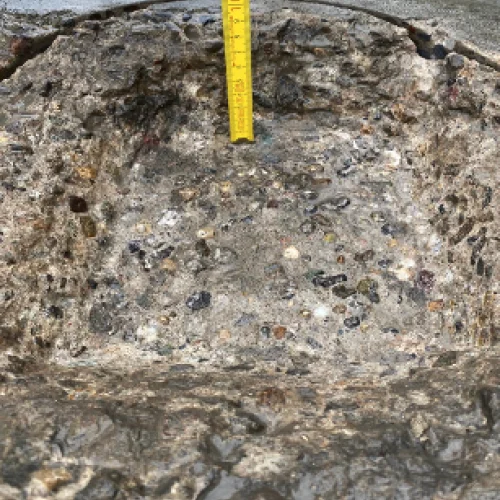

The panel is installed at the same level as the parking space. In a long-term test over 12 years, the panel has proven to be an excellent protection. Despite extreme wear and tear, there was hardly any abrasion on the panels.

Ultra-high-strength concrete 150 N/mm², very abrasion-resistant, dimensionally stable and with a strength comparable to that of granite and steel.

Concrete color is standard. Available in any color for an additional charge, e.g. your house color. However, when colored, the concrete loses 10% of its hardness!

The panel is installed at the same level as the parking space. In a long-term test over 12 years, the panel has proven to be an excellent protection. Despite extreme wear and tear, there was hardly any abrasion on the panels.

Ultra-high-strength concrete 150 N/mm², very abrasion-resistant, dimensionally stable and with a strength comparable to that of granite and steel.

Concrete color is standard. Available in any color for an additional charge, e.g. your house color. However, when colored, the concrete loses 10% of its hardness!

The concrete block is used for paved and asphalt surfaces and is installed as a holder for our plastic panels approx. 1 cm higher than the parking space level.

The 3 concrete block variants each have an integrated holder for our Basic plate variants.

Concrete with a minimum strength of C40/50, very abrasion-resistant, durable and dimensionally stable.

Dimensions: L= 750 mm x W= 750 mm x H= 200 mm.

Standard is concrete colour. But also available in other colours, painted with concrete paint.

The concrete block is used for paved and asphalt surfaces and is installed as a holder for our plastic panels approx. 1 cm higher than the parking space level.

The 3 concrete block variants each have an integrated holder for our Basic plate variants.

Concrete with a minimum strength of C40/50, very abrasion-resistant, durable and dimensionally stable.

Dimensions: L= 750 mm x W= 750 mm x H= 200 mm.

Standard is concrete colour. But also available in other colours, painted with concrete paint.

My name is Ulrich Lennarz, Managing Director of BOTEC Stellplatztechnik GmbH. I would like to tell you about our history and some important information about our company.

It all started in mid-2020 - At that time, I was working with my company BOTEC GMBH Tank- und Umweltschutz for Iwanautic SL in the area of parking space renovations.

In the period from January 14, 2021 to January 14, 2024, I then leased the operational business or part of the business of Iwanautic SL and operated it on a trial basis with the newly founded Iwanautic GmbH, with the aim of acquiring the part of the business.

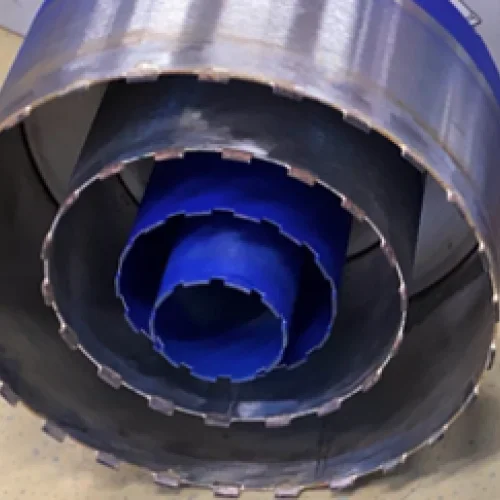

During this time, we have brought the construction site operations forward with a number of innovative modernizations. This included the use of a modern drilling machine, core drilling with multiple crowns and horizontal sawing of the hole circles in order to offer a vibration-free installation. Furthermore, in response to customer requests, we developed the 500 mm plate and brought it into production.

Unfortunately, Iwanautic SL has decided not to sell the operating part.

Therefore, there have been significant changes in our company as of January 15, 2024:

Our company name has changed: IWANAUTIC GMBH has become BOTEC Stellplatztechnik GmbH .

We have moved and our postal address has changed to: Alte Heerstraße 78, 53757 Sankt Augustin

Our email address has changed to: info@botec24.eu

Our telephone number has changed to: +49 (0) 228 28669716

Our website has changed to: www.botec24.eu

Our product range has been expanded to include: floor panels made from a plastic-steel compound and high-strength concrete.

But for our customers nothing has changed apart from the above master data and positive product expansion.

All contracts, guarantees, warranties and our terms and conditions of business, sale and delivery remain unchanged.

We are still the reliable partner with modern equipment, trained specialists and high-quality products!